Efficient production planning is the key to business success in the current competitive production market. Enterprises require real-time insights, maximised resource efficiency and continuous synchronisation of demand with supply. This is where SAP PP (Production Planning) comes into the picture.

What is SAP PP?

Transforming Production Planning to SAP Production Planning in SAP ERP and SAP S/4 HANA is a key functional module for planning, scheduling, executing, and controlling the production of goods.

SAP PP helps Organisations

- Plan production based on demand

- Manage raw materials and resources

- Control manufacturing costs

- Optimize capacity utilization

- Guarantee the delivery time of finished products

SAP PP essentially helps in closing the gap between sales demand and production execution, which makes it essential to implement it for various manufacturing industries.

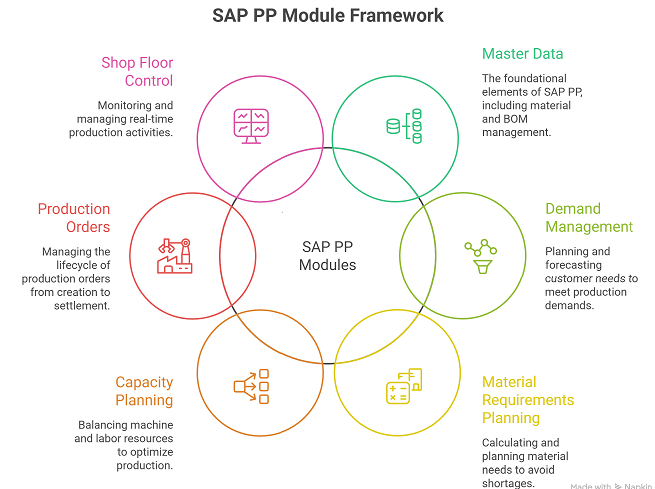

Let us explore in detail the various SAP Modules:

SAP PP Modules

SAP PP components knowledge should be acquired for learning the modules.

- Master Data

The foundation of SAP PP:

- Material Master

- Bill of Materials (BOM)

- Work Centers

- Routings

- Production Versions

- Demand Management

- Planned Independent Requirements (PIR)

- Sales orders and forecasts

- Material Requirements Planning (MRP)

- Calculates material shortages

- Generates procurement proposals

- Plans production schedules

- Capacity Planning

- Checks the machine and labour availability

- Balances workload

- Production Orders

- Creation, release, confirmation, and settlement

- Tracks actual production costs

- Shop Floor Control

- Monitors real-time production activities

| SAP PP Modules | ||

| Module No. | Module Name | Sub Module |

Module 1 | Introduction to SAP PP | Overview of ERPERP architectureImplementation methodsSAP PPQuiz Module 1 |

| Module 2 | Condition tablesAccess sequenceStrategy typesClasses and Characteristics, SLED in batch in PPAutomatic and manual batch displayQuiz Module 12 | Enterprise StructureQuiz Module 2 |

| Module 3 | Factory Calendar | Factory CalendarQuiz Module 3 |

Module 4 | Planning | Production planningLong-term planningMPS and MRPQuiz Module 4 |

| Module 5 | Capacity Planning | Purchase the information reportQuiz Module 5 |

Module 6 | Manufacturing | Discrete man SA SAP PP Training CourseManufacturingProduction planningPP REMQuiz Module 6 |

Module 7 | Master Data | Material MasterBOMQuiz Module 7 |

Module 8 | Production Order | Development and release of the orderPlanning integrationOrder printing and material stagingWork CentreRouting typesProduction versionCheck availabilityOrder control and processing, Confirmation of orderReceipt of goodsInformation systemCollective orderQuiz Module 8 |

Module 9 | Variant Configuration | Classes and variantsClassification profileDependenciesQuiz Module 9 |

Module 10 | Sales and Operational Planning | Product group planningMaterial planningStandard planningDevelopment of planDemand managementQuiz Module 10 |

Module 11 | Planning Material Requirement | Master data requirementsMRP vs MPSMaster productionProcessed planned ordersOrder conversionMaster production scheduling planning runQuiz Module 11 |

Module 12 | Batch Management | Condition tablesAccess sequenceStrategy typesClasses and Characteristics SLED in batch in PPAutomatic and manual batch displayQuiz Module 12 |

| Module 13 | Repetitive and Discrete Manufacturing Process | Master data maintenanceProduction versionsBackflushingREM backflushingREM ProfilingQuiz Module 13 |

| Module 14 | Integration with QM and MM | Integration with QM and MMQuiz Module 14 |

SAP PP Functionality

The full manufacturing life-cycle is supported by the SAP PP functionality.

Key Functional Capabilities

- Demand forecasting and planning

- MRP execution

- Production order management

- Capacity leveling

- Cost calculation

- Production reporting and analysis

SAP PP is flexible enough to support both process manufacturing and discrete manufacturing, which are different industry requirements.

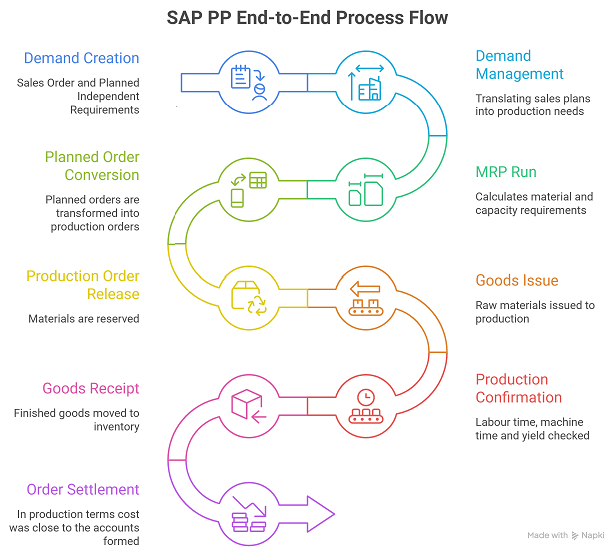

SAP PP Process Flow (End-to-End)

It’s important to know the SAP PP Process Flow for both Learning and Implementation of SAP.

Step-by-Step SAP PP Process Flow

Demand Creation

- Sales Order and Planned Independent Requirements.

Demand Management

- Translating sales plans into production needs

MRP Run

- Calculates material and capacity requirements

- Creates planned orders and purchase requisitions

Planned Order Conversion

- Planned orders are transformed into production orders

Production Order Release

- Materials are reserved

- Shop floor execution begins

Goods Issue

- Raw materials issued to production

Production Confirmation

- Labour time, machine time and yield checked

Goods Receipt

- Finished goods moved to inventory

Order Settlement

- In production terms cost was close to the accounts formed.

Structured determinations provide accuracy, transparency and efficiency.

SAP Features

It is a robust solution that comes up with N-number of features, in terms of advanced SAP PP.

Top Features of SAP PP

- Real-time production planning

- Automated MRP Calculations

- Capacity planning and levelling

- Cost tracking and variance analysis

Integration with SAP S/4HANA

From small to large businesses, the opportunity is scalable.

Support for Industry 4.0 initiatives

SAP PP has become faster now with SAP S/4HANA, predictive MRP and Fiori-based UX.

SAP PP in SAP S/4HANA

SAP PP in S/4HANA introduces:

- Embedded analytics

- MRP Live

- Simplified data models

- Faster decision-making

These are the new features in SAP PP that will be future-proofing for smart manufacturing and digital factories.

SAP Configuration

SAP PP Configuration is adjusted to the business requirements of companies during implementation.

Key SAP PP Configuration Areas

- Organizational Structure

- Plant

- Storage location

- Production scheduler profile

- Master Data Configuration

- BOM usage

- Routing selection

- Work centre categories

- MRP Configuration

- MRP types

- Lot sizing procedures

- Scheduling parameters

- Production Order Configuration

- Order types

- Status management

- Confirmation parameters

- Integration Settings

- Discussion on MM, SD, QM & FICO integration

SAP PP configuration requires strong business process understanding, making professional consultants with upgraded SAP PP skills highly valuable.

Who Should Learn SAP PP?

- Engineering graduates

- Supply chain professionals

- Manufacturing executives

- SAP MM or SD consultants

- ERP professionals seeking specialisation

With proper training and real hands-on experience, SAP PP provides opportunities for long-term career development.

Eduwatts: No.1 SAP Training Institute

Eduwatts is the premier online platform for SAP education, assisting learners globally. Numerous students and professionals from various backgrounds select Eduwatts for Online SAP PP Training Course. We provide outstanding SAP PP instruction led by skilled trainers. Our virtual sessions are just as effective as traditional in-person classes, enabling you to engage with your instructor and fellow students. You have the flexibility to learn at your own speed, whenever and wherever you choose.

For dedicated professionals aiming to elevate their careers and become leading executives, we help you enhance your competencies for SAP positions. Our professional SAP Institute not only teaches the use of SAP software but also equips students for employment in organisations that implement SAP.

What do Eduwatts offer?

- Online SAP Training

- Hands-on Project

- Real-time case studies

- SAP Expert Trainers

- Upgraded SAP Curriculum

- Placement Assistance

- Interview Preparation

On successful completion of SAP PP training, you will get the SAP PP Certificate. The Certificate is not only a proof of qualification update, but also the passport to your career. You can apply for top SAP job positions around the world.

Top SAP Courses

The following list highlights the most sought-after SAP Training Courses among students and professionals aspiring to become SAP professionals:

- SAP PP Training Course

- SAP EWM Course

- SAP FICO Course

- SAP HANA Course

- SAP ABAP Course

- SAP Simple Finance Training

Benefits of Online PP Training at Eduwatts

The following are the main benefits of pursuing an Online SAP PP Training Course from Eduwatts:

- Flexile Learning Hours – Learn on your terms with Batch availability as per your schedule.

- Expert Faculties – Learn from industry experts who hold years of experience in SAP PP.

- Detailed Curriculum – Explanation on Fundamental, Configuration and hands-on training along with the process flow covering MRP and capacity planning, including real-time scenarios.

- Exercises – Practical exercises and access to a test system during the course.

- Live doubt clearing – Weekly Q&A and one-on-one support.

- Assistance with Placement – Assistance in finding a job, critiques of resumes and practice interviews.

- Cost-Effective – Best of both worlds, keep costs down by eliminating travelling and lodging.

- Recorded Sessions – Replay of sessions for revision anytime.

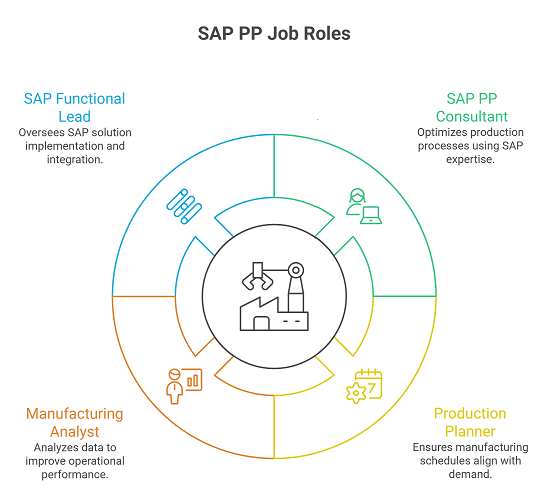

Career Scope

SAP PP training ismore than simply learning technical aspects. It’s about skill development and creating a job-ready career.

Why SAP PP is the Best Career Choice?

- High demand in manufacturing industries

- Global job opportunities

- High salary packages

- Strong integration with business processes

- Relevance in the age of Industry 4.0 and smart factories

Top Job Roles

- SAP PP Consultant

- Production Planner

- Manufacturing Analyst

- SAP Functional Lead

Conclusion

The SAP PP Module is the core of all SAP Manufacturing Modules. From demand planning to production scheduling, SAP PP optimises the way businesses are run – economically, effectively and competitively.

This has been the SAP PP complete guide:

- What is SAP PP?

- SAP PP architecture and components

- SAP PP functionality and features

- SAP PP Process Flow and Basic Configuration

The process applies to all types of products.

With the continuously advancing industrial revolution and digitalisation, SAP Production Planning is a crucial skill in process logistics! Regardless if you’re new or experienced, get ready to master SAP PP and see your career take off through the roof.

FAQs

Q1.What is the SAP PP module in SAP?

Ans. SAP PP (Production Planning) is a SAP module that provides userid to assist with the production planning of a company, and it facilitates production capacity and flow according to sales operations.

Q2. What are the Key elements of SAP PP?

Ans. Some of the important sub-components of SAP PP are Master Data and Production Planning (Demand Management Planning, MRP(Master Requirements Planning)). Capacity Requirement Planning, and so on.

Q3. What is the SAP PP process flow?

Ans. SAP PP process flow begins with demand creation, followed by MRP run to meet the demand, planned orders and production orders generation.

Q4. What do we use SAP PP configuration for?

Ans. The customisation of production planning in SAP PP by MRP settings, work centre, BOM, and routing define for the business requirements and planning to use those resources.

Q5. Is SAP PP a good career choice for the year 2026?

Ans. Yes, SAP PP is a high-revenue-generating opportunity because of the increasing manufacturing automation and more implementation of SAP S/4Hana or industry for 0 in global industries.